-

صفحة رئيسية > المنتجات >

reduction ratio of hammer mill

2019-11-07T18:11:30+00:00

Reduction Ratio Of Hammer Mill Steampot

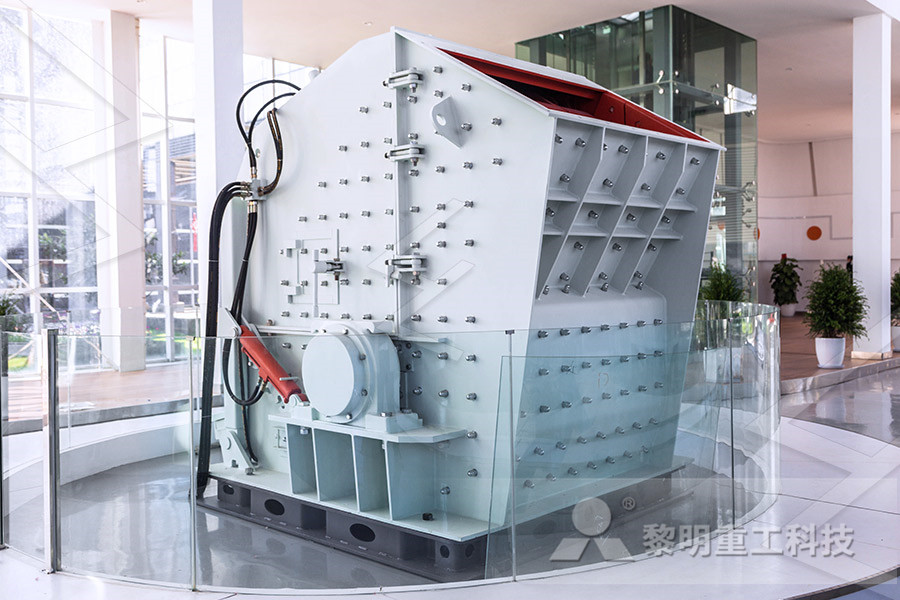

Reduction Ratio Of Hammer Mill For coarse reduction of grain, a roller mill may have a significant advantage perhaps as high as 85 percent over a hammermill in terms of throughputkwh of energyFor cereal grains processed to typical sizes 600 to 900 microns for the feed industry, the advantage is about 30 to 50 percentHammer mills crush materials into two (2) stages Size reduction which occurs by dynamic impact Sizing which occurs by attrition and shear in the second zone were small clearance exists between the hammer and the screen bar producing a particle range of 1550 micrometerHammer Mill AFSystems4/4/2020 The distance between hammer and screen should be 05 inches 12 to 14 mm for size reduction of cereal grainsThe velocity or tip speed of the hammers is critical for proper size reductionTip speed is calculated by multiplying the rotational speed of the driveHow Is Reduction Ratio Of Hammer Mill Calculated

REDUCTION RATIO FOR BALL MILLING Crusher Mills, Cone

standard number of reduction ratio of grinding mill 150 where RRO = optimum reduction ratio for the mill size = 8 long and tedious and requires a standard set of grinding conditions; mill size, ball charge etc ef3 ef6 ef8 reduction milling factor – Gold Ore Crusher Effect of 1/2/2013 Impact hammer mill produces selfsimilar distribution of product with a high reduction ratio Median size of product is exponentially related to the quantity of fines generated Reduction ratio and specific energy are linearly related The quantity of fines generated in Comminution features in an impact hammer mill ScienceDirectThe vertical shaft impact crusher size reduction ratio is 48 to 1 The vertical roller mill size reduction ratio is 225 to 1 The hammer crusher size reduction ratio is 20 to 1 Pre Article: Crusher Plays An Important Role In Artificial Sand Production LineCrusher Size Reduction Ratio Calculation Method

How Is Reduction Ratio Of Hammer Mill Calculated

The distance between hammer and screen should be 05 inches 12 to 14 mm for size reduction of cereal grainsThe velocity or tip speed of the hammers is critical for proper size reductionTip speed is calculated by multiplying the rotational speed of the drivein Particle Size Reduction Equipment 0 Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal caseHammer Mill: components, operating principles, types, uses Wetting or drying the grains can also modify them [17] found that increasing the screen size of hammer mill from 32 to 48 and 633 mm gave a decrease of 30 and 55% in grinding energy under operating conditions at drum speed 2930 rpm, no of hammers 12 hammer and moisture content 51%Grinding Parameters and their Effects on the Quality of

Hammermill Crushers McLanahan

The Standard and NonClog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output These are primary stage crushers, commonly followed with Centerfeed Mills or other types of secondary stage crushers The HammerMaster is also a secondary stage crusher in that the maximum feed size is 6" (150mm)Hammers should be balanced and arranged on the rods so that they do not trail one another The distance between hammer and screen should be 12 to 14 mm (~ 1/2 inch) for size reduction of cereal grains The velocity or tip speed of the hammers is critical for proper size reductionHammer mills: hammermills Feed Mill Machinery Glossary The size reduction should be performed using a shredding mill, hammer mill, pin mill, fluted rollers, or grinders Tobacco grinding may be considered as one prototype size reduction mechanism Plant materials containing a high content of stem and stalk are shredded with shredding mills The hammer mills are for friable materials Fluted roller grinders are for drugs having a high content of Size Reduction an overview ScienceDirect Topics

PHILIPPINE AGRICULTURAL ENGINEERING STANDARD PAES

62 The hammer mill should be used for the desired product having a reduction ratio of at least 50:1 63 The noise emitted by the hammer mill shall not be more than 96 db (A) * 7 Design, Workmanship and Finish 71 Hammers and perforated screen shall be accessible and replaceableThe modification in design of the hammer mill focused on the hammer pattern and arrangement; whereas the performance analysis was conducted based (PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING SIZE The hammer mill crushes by the collisions between highspeed hammer and material, and the hammer crusher features in its simple structure, high reduction ration, high efficiency, etcDesign and Fabrication Of Hammer Mill Mechanical Project

CERAMIC MATERIALS I metalurjimuedutr

Speciality crushers a)Rod mill b)Ball mill The reduction ratio is defined as the representative feed size by representative product size The sizes are usually defined as 1/3/2020 The hammer mill has the highest reduction ratio of 595 for coarsely ground corn, followed by the roller mill, whilst the multicracker system (see the description of multicracker in 23) has the smallest reduction ratio of 160 for coarsely ground wheatSize reduction in feed technology and methods for The size reduction should be performed using a shredding mill, hammer mill, pin mill, fluted rollers, or grinders Tobacco grinding may be considered as one prototype size reduction mechanism Plant materials containing a high content of stem and stalk are shredded with shredding mills The hammer mills are for friable materials Fluted roller grinders are for drugs having a high content of Size Reduction an overview ScienceDirect Topics

Crusher Reduction Ratio Mineral Processing Metallurgy

What is the impact of the Crusher Reduction Ratio on crusher performancesize reduction 3 Grinders like hammer mills, rollingcompression mills, tumbling mills, etc Grinders are used for intermediate and fine size reduction 4 Ultrafine grinders like hammer mills, agitated mills, fluidenergy mills, etc The basic motive behind performing the sizereduction is to make too large to be used solid materials usable It leads to an increase in surface area per unit FM 306: SIZE REDUCTION AND SIEVINGThe hammer mill crushes by the collisions between highspeed hammer and material, and the hammer crusher features in its simple structure, high reduction ration, high efficiency, etcDesign and Fabrication Of Hammer Mill Mechanical Project

Hammer mills: hammermills Feed Mill Machinery Glossary

Hammers should be balanced and arranged on the rods so that they do not trail one another The distance between hammer and screen should be 12 to 14 mm (~ 1/2 inch) for size reduction of cereal grains The velocity or tip speed of the hammers is critical for proper size reductionIn order to break down oversize product, size reduction equipment is employed, and while there are a variety of size reduction equipment types available, one option, the hammer mill, offers a reliable size reduction tool for many applicationsHammer Mills: A Reliable Solution for Particle Size ReductionThrough both our OEM partnerships and inhouse proprietary designs, Allegheny Manufacturing offers the best equipment solution for even the most challenging size reduction application Our line of hammer mills and grinders are ruggedly constructed to provide years of efficient production, and are ideal for either standalone processing or Hammer Mills Allegheny Manufacturing

Size Reduction Equipment

Hammer Mills 2 Rolling Compression Mills a Bowl Mills b Roller Mills 3 Attrition Mills 4 Tumbling Mills a Rod Mills b Ball Mill; Pebble Mill c Tube Mills; Compartment Mills A primary crusher operates on run of mine material accepting anything that comes from the mine face and breaking into 150250 mm (610 in) A Secondary crusher reduces these lumps into 6 mm (1/4 in) Grinders reduce This mill is mainly used for soft, mediumhard, fibrous, coarse granules, irregular shaped materials Rathi Hammer mill is rigid fabricated construction of casing having wear resistance bitters sandwiched between rotor discs mounted on rotor shaft which is supported by Rathi Hammer Mill – Rathi Engineering

reduction ratio of hammer mill

Reduction Ratio Of Hammer Mill Steampot Reduction Ratio Of Hammer Mill For coarse reduction of grain, a roller mill may have a significant advantage perhaps a